*Jeremiah originally wrote this article for the Tree Care Industry Magazine. It was first published in the March 2024 issue.*

From Tree First’s inception, we wanted to keep a low overhead. This makes sense for any startup, but we’re planning to maintain our leanness into the future. I don’t mean cheapness; we of course have operating costs and we like new and functional equipment. We collected some cool data over the course of 2023 that might be insightful for arborists considering going into practice for themselves.

The main goal behind staying lean is to avoid the bloat that tree care companies often struggle with. When they start out, they think they need certain things to be productive: big wood chipper, chip truck, a few big saws, maybe a loader, a couple guys. You’ve got to pay those things off, and if your wings aren’t fully spread yet, that can be a crippling challenge.

The example set by Big Arb results in most tree companies looking more or less the same: the same equipment, a website full of business-speak, and without anything that really separates them—no aura. We found that the tried and true model had some flaws, so we tried a different approach. Not to mention, we think the Big Arb business model is boring. Part of the fun and fulfillment we get as arborists and business owners is figuring things out.

And this is no exception.

Arboriculture is for people who like physical and mental challenges. Climbers especially know that feeling, whether you're pruning or removing trees. It ain't easy, and we love that sometimes.

Do you climb with the heaviest harness possible? Or do you like to climb feeling light and flexible? Tree First is an experiment that applies that philosophy to the tree care business.

So how’s it going?

We just finished our fifth year, earning the most revenue to date, while being as busy as possible. Too busy perhaps at times this year.

If you aren’t familiar with Tree First, we focus on tree preservation. We manage trees in a place where heavy pruning and removing trees are the only two options given to people. We did not want to be a for-profit tree-killing business masquerading as tree care, and we happened to be in the right place and right time to stand out as another option.

We understand not every area is the same, but we’ve found standing out as a young company to be easy so long as we are thorough, talk to clients like people, and above all, advocate for trees and nature.

Here is a breakdown of the types of jobs we did through 2023:

Lots to talk about here. Plenty of jobs were mostly pruning with the removal of a small dead shrub or something. To account for that level of crossover was too tedious. So the categories were determined by the main goal of the job.

Clearly pruning was our big moneymaker category this year. I’m thrilled that soil amending was the third highest percentage, and even more thrilled that insect treatment and tree removal were last. Storm damage was abnormally high for the year due to a series of consecutive ice storms in February and March. I don’t expect that percentage to remain consistent in the coming years.

Considering every meeting I have is basically a free consultation (because I talk so damn much), that consultation percentage only accounts for those who paid for one. Perhaps if I charged folks more often, that the consultation percentage would grow while the other categories would shrink. It probably comes out in the wash either way.

The assessment category includes all levels of risk assessments, soil analyses, and any other site analysis. It probably has some crossover with the consultation category.

The miscellaneous category contains mostly one-off jobs. It also includes things like cabling and propping. Plenty of pruning jobs had crossover with cabling, but again, couldn’t really be accounted for without producing a ton of data points.

The soil amending contains things like fertilization, developing soil improvement zones, and root crown excavations. Next year we have plans to expand this percentage with the creation of a lean “soil van”, much like how we’ve built a lean pruning van, which is shown below.

I’m thrilled at this breakdown overall. Alright, let’s keep going:

I’ve broken down our 2023 jobs into two categories: Non-saw jobs and saw jobs.

We couldn’t think of a better way to categorize them other than by calling them saw jobs and non-saw jobs. To generalize the way the public sees us tree folk, they probably think this graph looks more like 99% saw jobs. (And they’d be right about that in my region).

Another element we implement to stand out and stay lean is to encourage clients to keep their material on site following a job. Promoting environmental stewardship to clients has worked marvelously.

For non-saw jobs, there really isn’t anything that we leave behind. But for this upcoming explanation, I’m talking about the 62% of our jobs that were saw jobs.

We don’t operate in a rural or heavily forested area. In those areas, it is easy to chip debris into the forest or woodland. We work in a metropolitan area with lots of large trees, but very much an urban and suburban place.

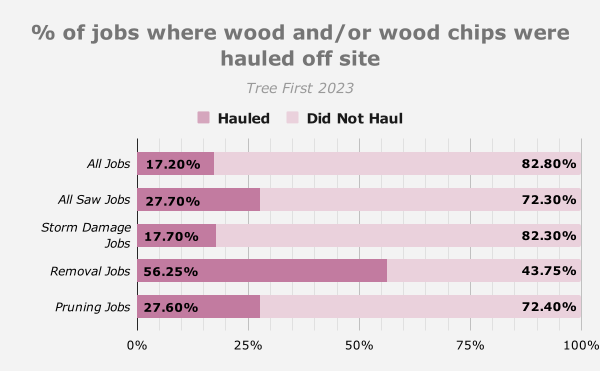

Here’s a breakdown of how often we hauled wood or wood chips off site:

Across all of our jobs, 17.20% of the time we hauled material from the site to somewhere else. Across all of our saw jobs (pruning, storm damage, removals), only 27.70% of those jobs required us to remove material off site. Compared to most tree outfits, I bet those are insanely low percentages.

For removal jobs, given they produce so much material, it is no surprise that we haul more than 50% of the time. But, in the grand scheme of things, removals only account for 4.5% of our overall jobs.

A lot of our arborist friends ask us how we get clients to keep the biomass on site. Here’s how.

Tree care falls under the domain of land stewardship; taking care of nature. When it is explained to people that your trees, your property, is part of an ecosystem, the remaining explanation falls easily into place. These aren’t big decorations, they’re functional elements to a broader system.

Brush and wood chips are a resource they’re paying us to remove, they see it as an item on their estimate. And if they can save money by not having us remove the wood chips from the site, 72.30% of the time they choose to keep them.

Hauling requires us to bring a dump trailer and sometimes a second vehicle. 72.30% of the time all we need to bring to a saw job is a single van, where our mobile chipper fits inside. It is a reduction of expenses across the board: emissions, time spent, fuel spent, vehicles deployed per job, space taken up at a job site, etc.. Inside our pruning van is our entire assortment of climbing, pruning, and rigging equipment. All of it.

Tree First’s pruning rig version 4

If you’re an arborist considering going into practice to take care of trees, I strongly urge you to exercise creativity in your business planning and equipping. Don’t just jump straight to going with the Big Arb form factor.

Hopefully this article is some proof of concept that there is room to be creative in this space, and the clientele are ready for a more modern approach. They also really appreciate commitment to making your practice better instead of doing the same ol’ thing.

This industry is especially prone to the American “bigger is better” mentality, but we’ve found smaller equipment isn’t necessarily under-engineered. Sure, some are, but there are top of the line small chippers that have all of the functions that large chippers have, and then some more. For example, our Eliet Prof 6 chipper is a self-propelled mobile unit. One of the many benefits of a smaller chipper, for example, is while pruning backyard trees, the drag path is only feet away from where the client wants the mulch pile.

When you don’t have 80k to spend on a chipper, you can still purchase a brand new machine at a fraction of the cost. The small chippers we’ve owned have each been worth their weight in gold. And same goes for our vans. Not to mention, smaller equipment and vehicles are easier to maintain and are more affordable. And if you plan to take care of trees, you probably don’t need a gigantic chipper. We don’t. And we don’t have plans to get one.

We understand the limitations of having a smaller rig, we can’t take down big trees or chip larger pieces of wood. Fine; we’ve equipped for the work we want to do, not the work we have to do to pay off big machines or a massive crew. When we do proper weight reduction, we’re seldom making cuts greater than 6” in diameter.

We want to keep trees around by reducing their risks and stress, and the costs and equipment for these things are simply much less expensive than the traditional Big Arb stuff. Not only that, you don’t need a huge crew to practice preservation. Tree First has been run and operated by only myself and Jack for its entire life so far. The practitioner approach is much more difficult when a company is built with a traditional big-arb setup and big-arb “always say yes” approach.

Some of my arborist inspirations began their business with vans too, but have since “graduated” to a big-arb setup. I don’t see the van builds as a stepping-stone. I see the van builds as an entirely different and equally viable path for a tree business.

This model works for us in our area because of our eco-centric approach as well as intentional choice in equipment. It only works because we work in that way; we advocate for nature through our practice. And if you work in the spirit of preservation, this can work for you too. Of course this doesn’t work if you’re only interested in removing trees. Not that those companies don’t have a need to exist–there is just an overabundance of them.

I always say the quality of the work is only as good as the hand that cuts (or sometimes, that hand that doesn’t cut). The Big Arb approach has compartmentalized and separated the roles of the arborist into many different roles: Climber, PHC tech, salesperson, etc.. The practitioner is all of those roles. There is no loss in communication with the clients because we are the ones making the plan with them, and we are the ones working on the tree. Clients love this, and we have become good students of arboriculture in the process.

This experiment is amazingly fun and rewarding, and I wouldn’t want any other good arborists to hesitate on going on their own. I think the practitioner model is the peak of arboriculture. To make the plan, to watch the tree, to climb it, to treat it, to amend its soil, to reduce its stress. To do the thing. All of it.

There are many examples of why the practitioner model can be a successful business model for those who want to eco-centrically practice, and who actually want to practice tree care and actually be about it.

If you’re an aspiring practitioner I encourage you to reach out to us. Jack and I have spoken to plenty of arborists about our project, and we’re happy to advise. It is more work to be a practitioner. It takes time to hone the craft. But then again, arborists like challenges. The practitioner-model has more facets to it, and perhaps we’ll share more in the future.